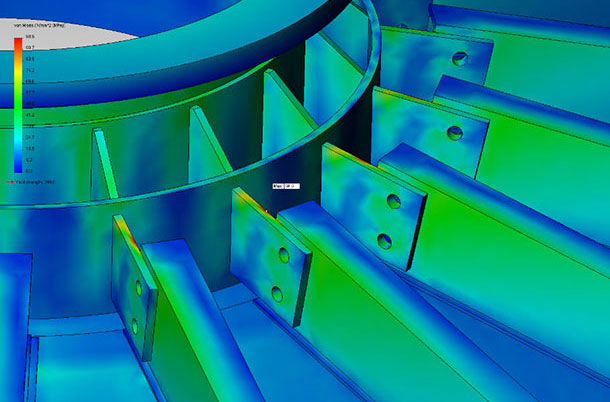

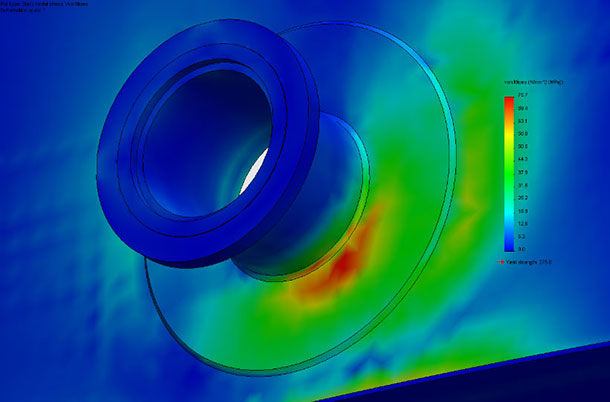

Finite Element Analysis (FEA)

We undertake FEA work for a range of engineering industries and applications, and not just in storage tank design.

FEA is a computerised method for predicting how a product reacts to real-world forces. It is used to anticipate whether a product will break, wear out or work the way it was designed.

Our complete design engineering solution integrates finite element analysis to assess the potential effects of:

- Mechanical stress

- Mechanical vibration

- Contact between components

- Pressures

- Temperatures

- Fatigue

- Motion

We have extensive CAD capability find out more here.

FEA benefits

The benefit of incorporating FEA into the design process is that we can verify that your product will conform to your client’s performance criteria early in the design.

This can accelerate the product development process and if the results do not meet expectations, you can optimise the design at an early stage saving time and money.

FEA can be used on all materials and equipment and it is especially valuable whilst working with complex materials and geometries.

In some sectors FEA analysis can be a prerequisite to certification or validation. Our SolidWorks® software is recognised and approved by the insurance industry.

If you would like any information or to discuss your current or planned projects then please do not hesitate to contact us.

Whether it is design optimisation, troubleshooting, product qualification or independent finite element analysis of your products, we have the engineering expertise and experience to meet your needs.